Repair instructions

A Beginner’s Guide On How to Burping a Coolant System

Introduction

As a car owner, it’s crucial to stay on top of your vehicle’s maintenance to ensure it runs efficiently and lasts for years. One critical task often overlooked is burping or bleeding the coolant system. This procedure helps remove air pockets from the system, ensuring optimal cooling performance. Neglecting this step can lead to overheating or poor cabin heating, so let’s break down the process and the key things you need to know as a DIYer or pro mechanic.

What is Burping a Coolant System?

Burping the coolant system involves removing air pockets trapped within the system. These air bubbles can disrupt the proper flow of coolant, leading to inefficient cooling and possibly overheating. Burping helps evacuate these pockets and restore the system’s full functionality.

Pro Tip: Ensure the engine is completely cooled down before starting any work on the coolant system. Opening a hot system is dangerous and can cause burns from the pressurized coolant.

This is a coolant reservoir. This type won’t have a screw-on cap because it’s not designed to hold pressure. The coolant enters this bottle as it expands and then returns to the radiator as the engine cools, and the radiator valve opens.

This is a surge tank or “degas” tank. This type will be designed to hold pressure and will have a screw-on pressure cap and is typically the fill point for the cooling system

How the Cooling System Works

Before diving into the burping process, it’s important to understand how your car’s cooling system works. Coolant circulates through the engine, absorbing heat and then dissipating it via the radiator. Once it cools down, it recirculates. This cycle ensures that your engine remains at a safe operating temperature.

If air enters the system, it can prevent the coolant from circulating properly, causing the engine to overheat or the heater to malfunction. This is where burping the system becomes essential.

When Should You Burp the Coolant System?

The primary reason to burp the coolant system is when air is introduced, such as after draining and refilling the radiator, or when components like the radiator or water pump have been replaced. Without proper bleeding, air pockets will form and disrupt the system’s performance.

Note: Simply topping up the coolant in the radiator doesn’t guarantee that the entire system is filled. Air pockets can still exist within the engine block, hoses, or heater core. That’s when burping is necessary.

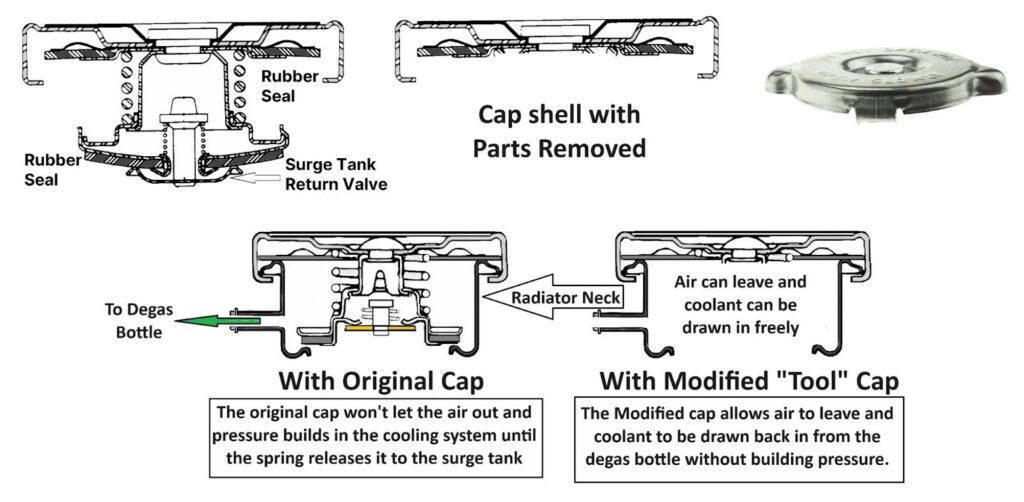

This is a good homemade tool for getting the air out of the system because it doesn’t allow the system to build pressure, which is dangerous

How to Burp a Coolant System: Step-by-Step

While the process can vary slightly between makes and models, here’s a professional guide you can follow for most vehicles:

Step 1: Let the Engine Cool

Never attempt to open the radiator cap while the engine is hot. The cooling system is pressurized, and hot coolant can spray out, causing serious burns. Allow the engine to cool before beginning.

Step 2: Add Coolant

Insert a clean funnel into the radiator and begin filling the system with coolant. Follow the manufacturer’s coolant-to-water ratio. The process may take some time, as air pockets in the system will cause the coolant level to drop intermittently.

Step 3: Squeeze the Upper Radiator Hose

To help dislodge trapped air, gently squeeze the upper radiator hose. This can help move the coolant through the system and release any air bubbles that may have formed.

Step 4: Open the Bleeder Valve

If your vehicle has a bleeder valve (usually located near the thermostat or radiator), loosen it carefully. You should hear a hissing sound as the air escapes. Once coolant starts to flow without bubbles, tighten the valve securely.

Step 5: Attach a Funnel to the Reservoir

If your vehicle has a surge tank or degas bottle, attach a funnel to the filler neck. This allows any remaining air to escape as the engine runs.

Step 6: Start the Engine

With the funnel attached, start the engine and let it warm up. This will cause the thermostat to open, allowing coolant to circulate through the system and push out any remaining air.

Step 7: Watch for Air Bubbles

As the engine runs, you’ll see air bubbles rise and escape through the funnel. This is normal and indicates that the system is being purged of air.

Step 8: Top Off the Coolant

Once the air bubbles subside and the coolant level stabilizes, let the engine cool down. Check the coolant level one last time and add more if necessary. You can now remove the funnel and securely replace the radiator cap.

Step 9: Test the System

Start the engine again and monitor the temperature gauge. The thermostat should open, and the coolant should circulate properly. If the fan cycles on and off without issues, you’ve successfully burped the system.

Pro Tips from the Pros

- Height Helps: Elevating the front of the vehicle can help air bubbles rise to the highest point in the system, making it easier to expel them. If possible, jack up the front of the car or park on a ramp.

- Airlift Systems: In some cases, an airlift system can be used to create a vacuum in the coolant system. This tool pulls air out of the system and helps ensure that all air pockets are removed.

- Bleeding with Aspirin: A trick some professional mechanics use is placing an aspirin tablet under the thermostat. The aspirin dissolves after about 15 minutes, helping to keep the thermostat open and allowing the coolant to flow freely, pushing air out of the system.

- Modified Radiator Cap: For those with a traditional radiator cap, it’s possible to modify an old cap to act as a tool for bleeding the air from the system. This method can be effective if you’re working with a degas tank or surge tank.

Final Thoughts

Burping the coolant system isn’t a complicated task, but it’s essential for maintaining your engine’s performance. By following the steps outlined above, you can prevent issues related to air pockets, avoid overheating, and ensure that your vehicle’s cooling system is running at its best.

Always remember, safety first! Never open a hot cooling system, and if in doubt, don’t hesitate to consult a professional mechanic.