Repair instructions

Do You Need a Suspension Bush Press?

Do You Need a Suspension Bush Press?

As a professional mechanic, I can tell you that using the right tool for removing suspension bushings is crucial for both efficiency and vehicle safety. The most effective and reliable way to remove suspension bushings is with a hydraulic shop press. It provides the hydraulic force needed to safely and precisely push out worn bushings and install new ones. However, this equipment isn’t always available for DIYers due to its cost and size. If you don’t have access to a hydraulic press, there are other methods, but they come with risks and require experience.

What Is the Best Suspension Bush Press Tool?

For professionals, the hydraulic shop press is the go-to tool for suspension bushing removal. This press uses hydraulic force to press out the old bushing and is also capable of installing new bushings with ease. It’s the most efficient and safe option, ensuring minimal risk of damaging other suspension components. However, due to its price and maintenance needs, it’s not a practical solution for most DIYers.

How To Remove Bushings Without a Press

If you’re tackling suspension bushing removal without a hydraulic press, there are a few alternative methods you can consider, but they all come with challenges. I strongly advise caution and only recommend these methods if you’re experienced with auto repairs.

1. Blowtorch Method

One of the most common alternatives is using a blowtorch to heat the bushing. This method is most effective for rubber bushings, which will soften and break down when exposed to high heat. Be cautious not to overheat or damage the metal shell around the bushing. Only use this method for rubber bushings—never for fluid-filled bushings, as it can be dangerous.

Pro Tip: Slowly heat the area around the bushing rather than applying direct flame to the bushing itself. This will allow the rubber to melt, leaving the metal shell intact for easier removal. Once the rubber has melted, you can use a metal tool to push the bushing out. Clean the housing thoroughly before installing a new bushing.

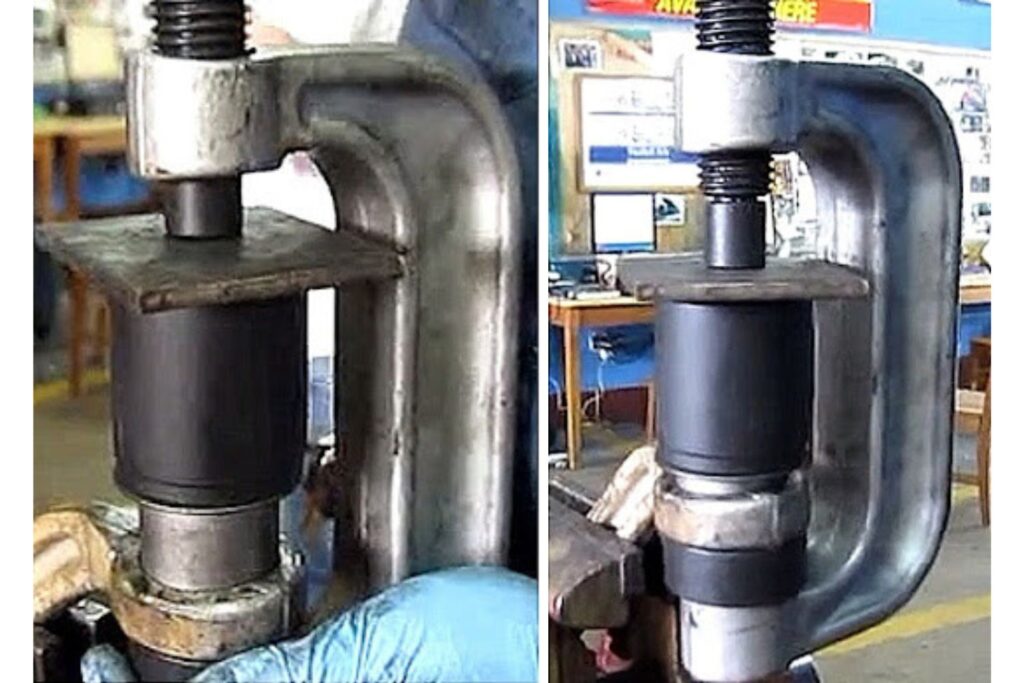

2. Threaded Press

If you don’t have a hydraulic press, a threaded press is another option. This tool uses mechanical force to push the bushing out. It requires a driver that matches the outer diameter of the bushing. Apply significant pressure with a wrench to rotate the screw jack of the press and push the bushing out. Be prepared to use some muscle, as it might take a lot of force to get the bushing free.

3. Hammer and Socket

This is the least ideal method but can work in a pinch. Use a socket that fits the bushing’s outer diameter and place it over the bushing. A few sharp strikes with a hammer should force the bushing out. However, this method is the most damaging and can ruin the bushing’s outer metal shell, making it unusable for reinstallation. This approach can also risk damaging other suspension components if not done carefully.

Final Thoughts

Regardless of the method you choose to remove the suspension bushings, always ensure that your vehicle’s alignment is checked by a professional afterward. Improper removal can lead to misalignment or other suspension issues, compromising vehicle safety and handling. When in doubt, it’s best to consult a mechanic for guidance or to have them handle the job, especially if you’re unsure about the proper tools or techniques.