Repair instructions

How To Inspect Car Coolant Hoses

Overview

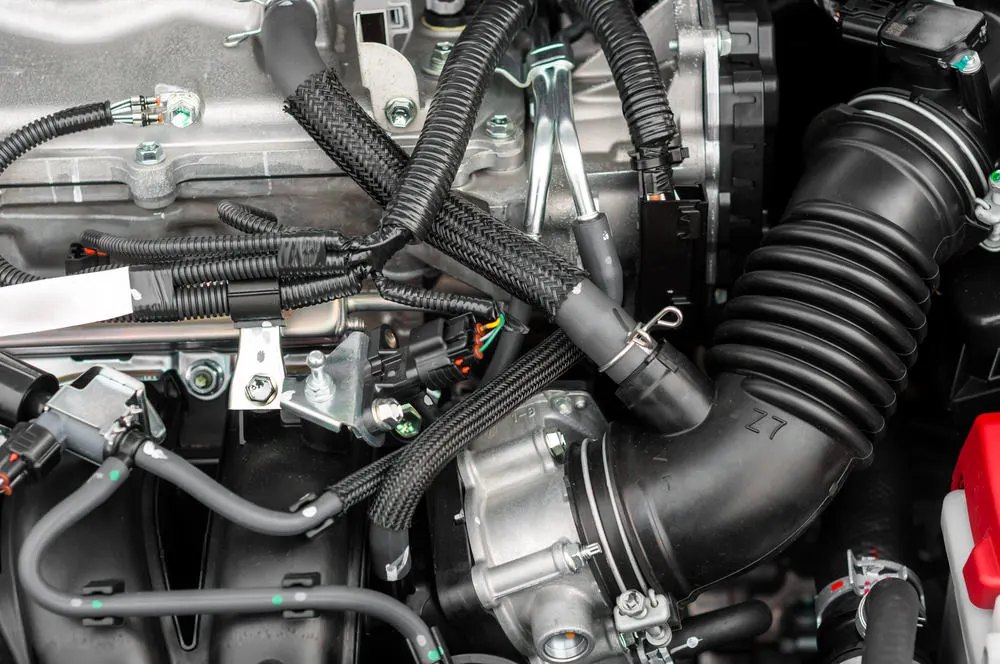

Coolant hoses are an essential part of your vehicle’s cooling system, designed to circulate coolant between the engine and radiator to keep the engine from overheating. Regular inspection and maintenance of your coolant hoses are critical to preventing leaks, overheating, and potential engine damage. By checking your hoses every 3,000 miles or so, you can ensure they remain in good condition and avoid costly repairs down the line.

How to Inspect Your Coolant Hoses

1. Warm Up the Engine First Before diving into your inspection, start by letting your engine warm up to operating temperature. This will help you spot any swollen or bulging spots on the hoses, which are often signs of internal pressure buildup. Additionally, you may notice damp areas near the hose ends, indicating potential coolant leaks.

Safety Tip: Always be cautious when working with a hot engine. Wear protective gloves, goggles, and thick clothing to avoid burns or injuries.

2. Perform a Visual Inspection Visually examine all coolant hoses for signs of wear, cracks, or bulges. It’s crucial to replace hoses that show any signs of deterioration before they fail and cause serious engine damage.

- Swollen Hoses: If a hose is noticeably swollen, back off immediately. A swollen hose is a serious safety risk. Turn off the engine and let it cool before replacing the hose.

- Damaged Hoses: A burst hose due to dry rot or high pressure can lead to coolant loss and engine overheating. Any visible damage should prompt a replacement.

3. Conduct a Squeeze Test Gently squeeze each radiator hose to assess its condition. A well-functioning hose should feel firm but flexible. If the hose is too soft, too stiff, or spongy, it’s time to replace it. A hose that doesn’t spring back to its original shape may have suffered internal damage or excessive wear.

4. Check for Cracks Examine the hoses for any cracks or fraying. Even small cracks can lead to major leaks, so replacing the hose as soon as you spot a crack is essential for preventing overheating. Additionally, ensure no hoses are in contact with sharp edges or hot engine parts, as this can accelerate wear.

5. Inspect the Clamps The clamps securing the hoses to the radiator and engine should be tight and free from corrosion. Over time, clamps can weaken or rust, leading to coolant leaks. Inspect each clamp, and replace or tighten them as necessary to ensure a secure fit.

Common Types of Coolant Hose Failure

Coolant hoses undergo significant stress due to exposure to high temperatures, chemicals, and pressure. Below are some of the most common types of hose failure:

1. Electrochemical Degradation (ECD) This form of internal damage is often hard to detect, as it occurs inside the hose. ECD causes tiny cracks to form, which can lead to hose rupture over time.

- Symptoms: Check the first 2 inches from the hose ends for signs of internal degradation. Hoses affected by ECD will feel soft at the ends and may show internal gaps when squeezed.

- Cause: The different metals in your vehicle’s cooling system generate an electric charge that can damage the hose internally.

- Solution: Replace the affected hose with a new one.

2. Leakage If you find coolant puddles under your car or notice coolant marks around the hoses or connectors, there’s a good chance you’re dealing with a leaking hose.

- Symptoms: Look for coolant residue on the hose or around clamps.

- Cause: Leaks are typically caused by worn-out hoses, faulty connectors, or improperly tightened clamps.

- Solution: Tighten the clamps or consider switching to constant-tension clamps. If the hose is worn, replacing it is your best bet.

3. Heat Damage Over time, heat can take a toll on your coolant hoses, making them brittle, hard, and prone to cracking.

- Symptoms: Heat-damaged hoses will have a glossy, cracked surface and may appear swollen.

- Cause: Prolonged exposure to engine heat, sudden temperature fluctuations, and low coolant levels contribute to heat damage.

- Solution: Replace the damaged hose with a new one.

4. Ozone Damage Exposure to ozone from environmental pollution can break down the rubber compounds in the hose, causing cracks and deterioration.

- Symptoms: Look for tiny, parallel cracks on the hose’s outer surface.

- Cause: High ozone levels weaken the rubber’s molecular bonds, causing premature aging and failure.

- Solution: Replace the hose with one made from EPDM (ethylene propylene diene monomer), a more durable material resistant to ozone damage.

5. Abrasion Damage In compact engine bays, hoses can rub against other components, causing wear and tear over time.

- Symptoms: Look for rub marks, holes, or cracks in the hose.

- Cause: Friction from engine parts rubbing against the hose causes the material to wear away.

- Solution: Reroute the hose, install a protective cover, or replace the damaged hose.

6. Oil Contamination Oil can weaken the rubber in your coolant hoses, making them soft, swollen, or prone to bursting.

- Symptoms: Oil contamination causes hoses to feel soft, spongy, and swollen.

- Cause: Leaking oil, typically from a faulty head gasket, contaminates the hose and weakens the rubber.

- Solution: Replace the damaged hose and fix the source of the oil leak.

Final Thoughts

Regular inspection and timely replacement of coolant hoses are vital to keeping your engine running smoothly and avoiding costly repairs. By following the steps outlined here, you can detect early signs of hose failure and prevent more significant issues with your vehicle’s cooling system.

If you’re unsure about the condition of your coolant hoses or need help with the replacement process, don’t hesitate to consult with a professional mechanic. Proper maintenance is key to ensuring your vehicle stays cool and performs optimally.